Production Facility

Standards That Make Our Production Unique

From ventilation systems to sterilization processes, every detail is specially designed to protect human health and ensure product reliability.

What is the Advantage?

In our company, two air conditioning units are used to maintain optimal temperature, pressure, and moisture (humidity) levels within the production areas. These units are equipped with G4, F7, F9, and HEPA filtration systems. This setup ensures that the air circulating in the production areas is effectively filtered and free from particulate contamination, providing a clean and controlled air environment.

Product Safety

As a result, production takes place under the most accurate conditions. The maintenance of the air conditioning and climate control units are conducted periodically by our technical team and documented accordingly.

What is the Advantage?

Ozone is crucial in pharmaceutical production due to its powerful antimicrobial properties, effectively inactivating bacteria, viruses, fungi, and spores without leaving harmful residues. It is used for the purification of both water and air within facilities, ensuring thorough sanitation and an aseptic environment. This minimizes the risk of cross-contamination and supports the production of safe, high-quality pharmaceutical products.

Environmentally Friendly

Ozone decomposes back into oxygen, leaving no toxic by-products, aligning with sustainable production practices. By integrating ozone, we ensure the highest sterility standards, promote sustainability, and enhance economic efficiency, ultimately delivering safe, high-quality products.

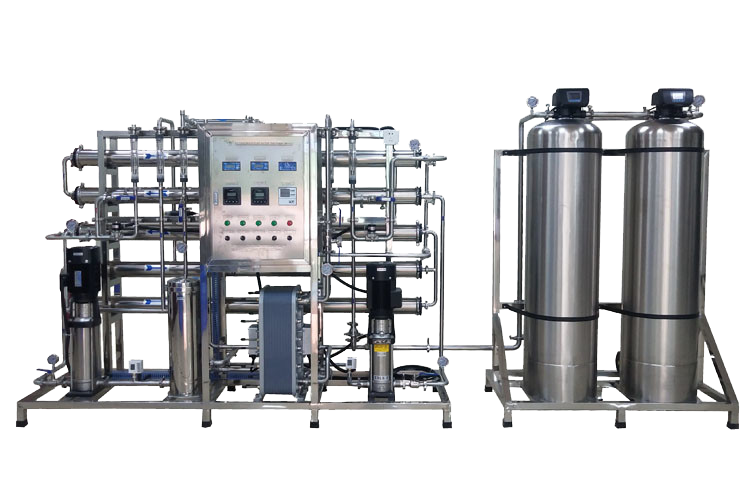

What is the Advantage?

Our company employs a Reverse Osmosis DI water system. This system uses sand filters, activated carbon, resin, membranes, mix bed, and two UV lamps to purify municipal water into DI water suitable for production.

The Quality of the DI Water System

Is monitored through regular sampling by the quality control team. Maintenance and cleaning procedures are performed periodically by the technical team and are thoroughly documented.

What is the Advantage?

We require the daily use of new, fully enclosed sanitary clothing in our manufacturing area to prevent human particles from contaminating the production sites.

- Sanitary Protocol

- Contamination Control

- Hygiene Compliance

What is the Advantage?

It is built and used in a way that minimises particle entry, proliferation and retention, where the concentration of particles flying in the air is constantly kept under control by measurements, as well as temperature, humidity, pressure, air flow lines, etc.

And Also

We use special rooms where other variables are kept under control. In addition, due to our meticulousness regarding health and hygiene, our floor is covered with special materials that do not retain water and prevent the formation of bacteria.

Get To Know Our Factory Machines

All of the following machines arecustom-made specially for our factory.

All the machines we use in dietary supplement production are advanced technology systems selected in accordance with GMP and ISO 22000 standards. From filling to packaging, every stage is precisely controlled to ensure maximum hygiene and product quality.

Our Weighing Scale Devices

What is the Advantage?

Our setup features an advanced automatic labeling system that’s tightly linked with our ERP. This setup ensures that every step of the process is rigorously controlled, sticking to exact product recipes and set limits without deviation.

And Then

After each weighing, the scoops are meticulously cleaned, and the measured ingredients are packed in food-grade PE bags and stacked on the product pallet.

Cubic Powder Mixer

What is the Advantage?

Raw materials are added to the tank in the specified order. In our machine, which is made of first-class stainless materials, sieves are used to ensure that the raw materials to be mixed are of the same particle size and to ensure homogeneity.And Also

After the mixing process is completed, the quality control laboratory takes samples and performs moisture and homogeneity tests.

Our Capsule Filling Machine

What is the Advantage?

The product is taken to the capsule filling process. Both herbal and gelatin capsules are filled in our semi-automatic capsule filling line. Our capsule filling machine is **Capsugel** brand, and only capsules of the same brand are used. The number of capsules is controlled by the production operator at each filling time.

In Addition

Double checks are carried out by IPC every half hour. A selection and automatic polishing process is applied to ensure that we deliver our products to the consumer at the highest quality.

Our Blister Packing Machine

What is the Advantage?

A blister packaging machine is used in the primary packaging of our capsule, tablet, and softgel products. It makes the product packaging more sealed, moisture- and light-proof, and improves product quality.

After Automatic Filling Processes

Optical control is performed to ensure that our products are perfect.

Capsule Selecting and Polishing Machine

What is the Advantage?

Our capsule polishing machines, where the points in contact with the product are made of stainless materials, also provide the advantage of creating a hygienic working environment.

And Also

In fact, our capsule polishing machines’ anti-bacterial silicone bristled cleaning brushes, anti-bacterial filter, and stainless steel body enable full hygiene across all other productions, including pharmaceuticals.

Our Tablet Press Machine

What is the Advantage?

After the product mixing process is completed and approval is received from the quality control department, we feed the product to the tablet press machine. Before the pressing process begins, the tablet is subjected to hardness, dispersion, and friability tests by IPC and the operator. Once suitability is achieved, the tablet pressing process is started, and analyses continue every half hour.

At the Same Time

All surface areas of the machine are made of stainless steel, and the points in contact with the product are dismantled and cleaned at the end of each process.

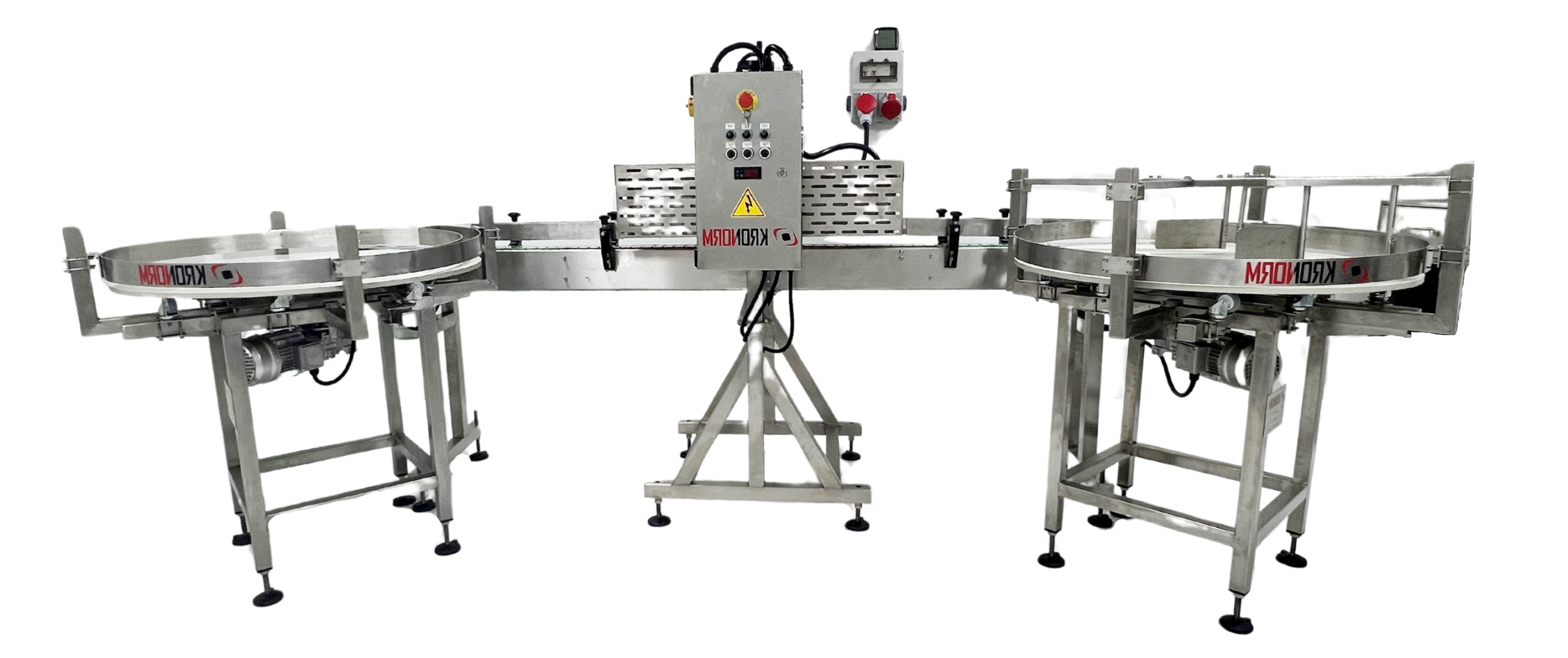

Our Sleeve Machine

What is the Advantage?

Products whose filling and primary packaging are completed are taken to the packaging line.

After the bottle filling process, a body-sleeve or security tape is applied to protect the product, and the boxing process begins.

What is Being Checked

Product-specific information, such as serial number and expiration date, is checked by IPC.

During the packaging process, a box label is attached to the completed boxes, which are then placed on pallets. Completed pallets are delivered to the warehouse with a pallet label attached.

Liquid Production Tank

What is the Advantage?

By automatically drawing the required amount of water from our water system into the tanks, verification is made with the scale in the tanks. After the previously validated production is completed, a sample is given to the quality control laboratory for analysis.

And Then

When conformity approval is received, the product is transferred to the liquid filling machine with the automatic feeding unit, without contamination from humans or air.

Our Liquid Production Machine

What is the Advantage?

In the double-nozzle automatic liquid filling machine, which operates as a closed process, filling, nitrogen filling, capping, and labeling operations are carried out in a sequential manner. In our filling line, a **Festo** head label machine of German origin is used, and in the label machine connected to the line, a **Herma** head label machine of German origin is employed.

Production Controls

During the filling process, density, pH, and quantity checks are performed by the production operator and IPC every half hour.

Our Liquid Product Filling Machines

What is the Advantage?

Our machines automatically take the product to be filled directly from the manufacturing tank. Thanks to this feature, quality production is achieved by protecting the product from contamination.

At the Same Time

Bacterial growth and contamination are prevented through the high surface smoothness and argon welding technology.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Tartım Terazisi Cihazı

Avantajı Ne?

Kurulumumuz, ERP’mizle sıkı bir şekilde bağlantılı olan gelişmiş bir otomatik etiketleme sistemine sahiptir. Bu kurulum, sürecin her adımının titizlikle kontrol edilmesini, kesin ürün tariflerine ve belirlenen limitlere sapma olmadan bağlı kalınmasını sağlar.

ve sonra

Her tartımdan sonra kepçeler titizlikle temizlenir ve ölçülen bileşenler gıdaya uygun PE torbalarda paketlenir ve ürün paletine istiflenir.

Our Warehouse and Raw Material Storage Area

The storage process of our products is a critical component of our quality standards. All supplements are stored in facilities with strictly controlled temperature, humidity, and light conditions, supported by a batch-based traceability system. Prior to shipment, each product undergoes a final inspection by our quality control team and is packaged under strictly hygienic conditions.

Advantages

We have a 100-pallets warehouse equipped with a ventilation system to store raw materials and packaging under appropriate and controlled conditions. Ozone treatment is applied in the warehouse areas to maintain a clean and hygienic environment. For moisture-sensitive materials, humidity-controlled storage areas are available within the raw material warehouse.

Instead of This

For effective stock control and GMP-compliant production, all warehouse operations are managed through a barcode-based traceability system, ensuring fully controlled and error-preventive processes in weighing and inventory management.